- TOP

- THE MEASURE FOR SAFETY

THE MEASURE FOR SAFETY

to ensure food safety and security

Toyota Tsusho Foods Corporation has a Quality Assurance Group consisting of officers

with specialist quality assurance knowledge. We employ a comprehensive quality management structure

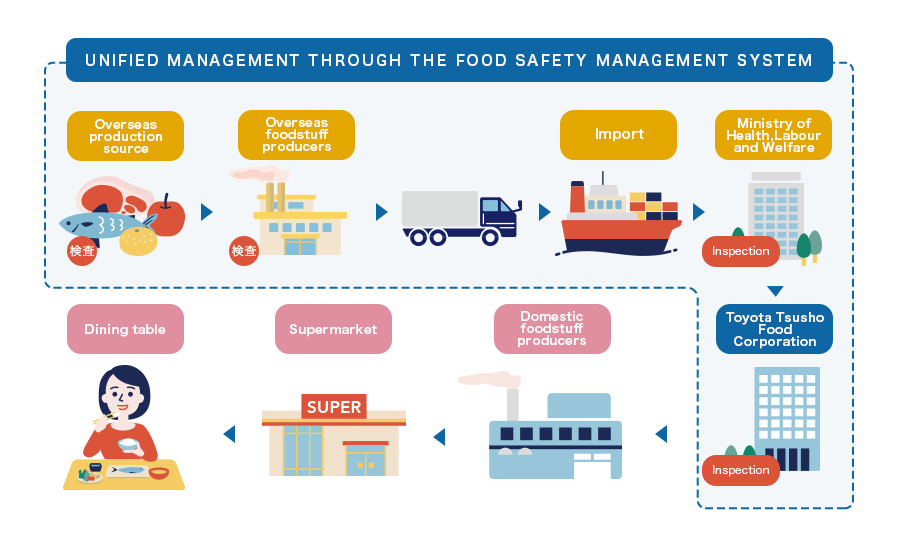

based on our proprietary food safety management system in order to manage suppliers,

comply with food laws and regulations, and train our personnel.

Action 1

with our food safety management system

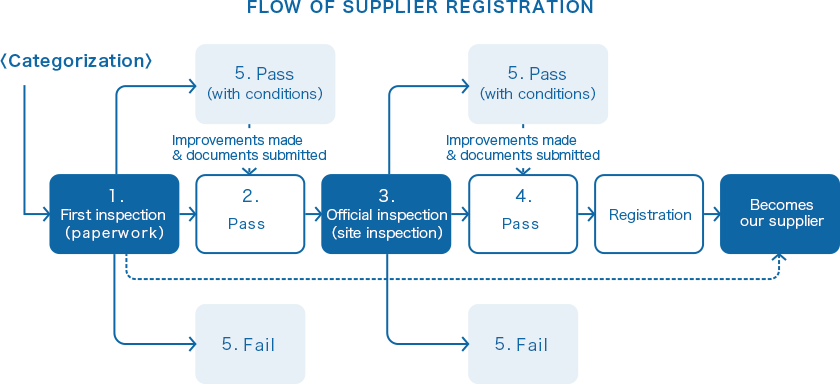

All of our suppliers trade with us on a registration basis.

We do business only with suppliers that meet specific criteria (we do not do business with unregistered suppliers).

- ・ Based on our unique checklist, our Quality Assurance Group inspects the supplier's local quality management structure to ensure product safety.

- ・If issues are identified during the inspection, the group instructs the supplier to make improvements and issues plant management instructions to the supplier.

- ・Even after we start doing business with a supplier, we continue to conduct periodic inspections in order to check the supplier's plant management structure based on previous points we have raised as needing improvement.

| Checked item | Main content |

|---|---|

| Organizational management structure | How management documents are organized & how quality management is inspected |

| State of efforts on compliance, appropriate response to claims | |

| Process management | Acceptance inspections, production process management criteria, work procedure manuals |

| Prevention of contamination and entry of foreign substances, managing the use of additives | |

| Basic management | Five keys for a safe plant and premises (organization, tidiness, cleaning, hygiene, discipline) |

| Pest control, cleaning/washing/sterilization methods, food defense | |

| Employee management | Conducting carefully planned training, dress code, shoes, grooming |

| Prevention of contaminants (e.g., hair), conducting medical checkups and stool tests | |

| Building & facility management | Employee entrances/exits, doors, hand-washing, shoe-washing, washrooms |

| Checking raw materials at the entrance and final products at the exit |

Action 2

We collect information, including updates on the following matters,

in a timely manner, and we inform relevant divisions to ensure safety.

● Response to relevant laws, regulations, and criteria updates:

We share information on food/food additives/pesticide remnants/animal drug criteria and regulation updates as well as on changes to inspection targets and items subject to government orders and monitoring.● Response to incidents by other companies:

We share cases of legal violations and accidents at other companies in order to prevent accidents in advance (our relevant divisions notify and warn suppliers).● Checking of food labelling and product specification documents:

We check the food labels of our products and product specification documents that we submit to customers. We also give guidance to suppliers on points to note regarding food labelling.

Action 3

We conduct food safety training as described below for all of our employees.

- ● We provide education to our employees in order to improve their expertise with respect to basic food knowledge, food safety, and food-related laws and regulations (on pesticide remnants, food additives, and hygiene standards).

- ● We provide our employees with knowledge of hygiene control for each food item so that when they visit supplier plants, they are able to inspect the plant's hygiene control.

- ●We strive to raise employee awareness on food safety by sharing information on food-related accidents in order to prevent such accidents.